12V Portable Air Compressor Inspection

Every season you should inspect and lube your compressor.

I have a 3 week outback trip soon and have just done an inspection and lube on my MK3 compressor. See below how it is done.

1) First make sure the compressor is clean and free of any sand.

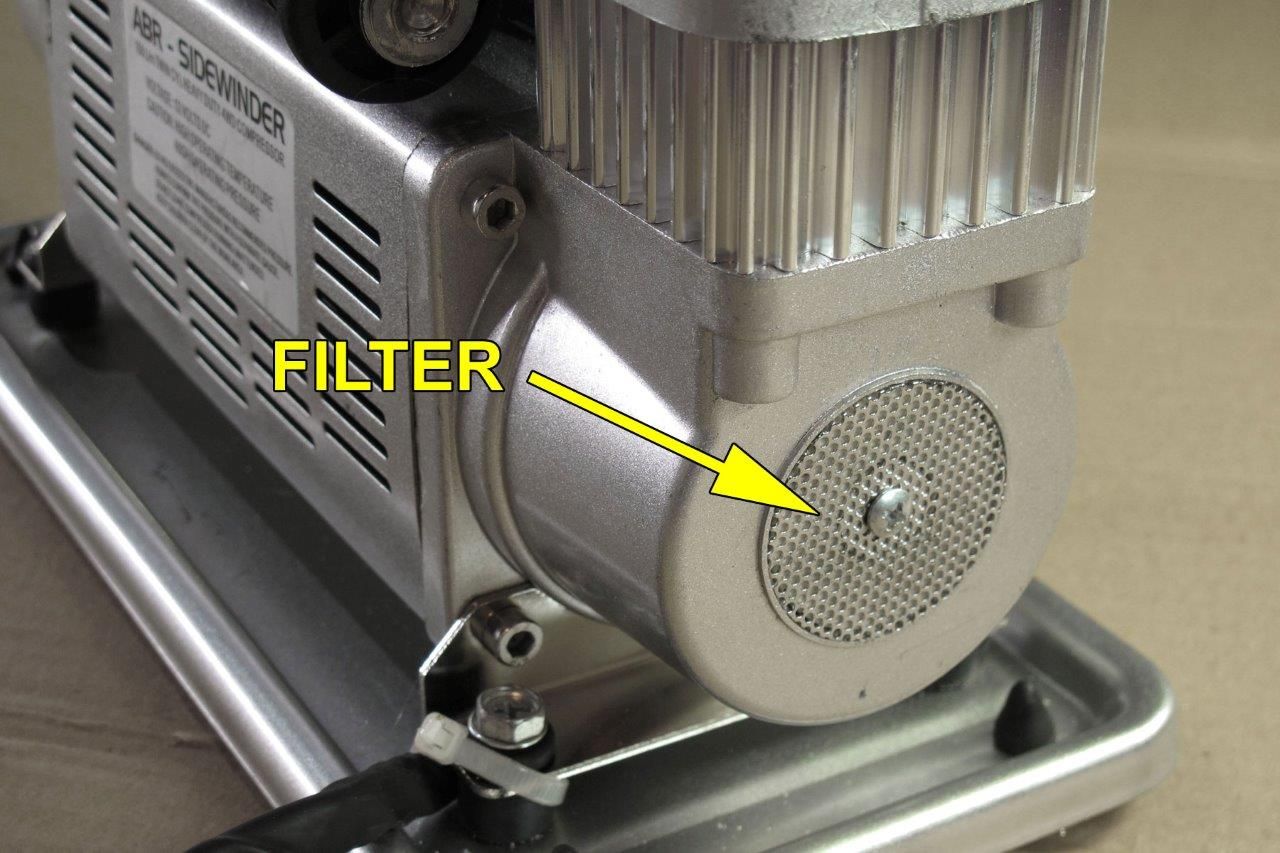

2) Remove the two filters and blow them clean.

3) Run the compressor and spray a good quality aerosol lubricant into the intake. Only a quick spray is needed,

approx. 3 seconds each side to lubricate the internal reed valves and prevent internal alloy parts from oxidizing.

4) Replace the filters and wipe the compressor down with a clean cloth.

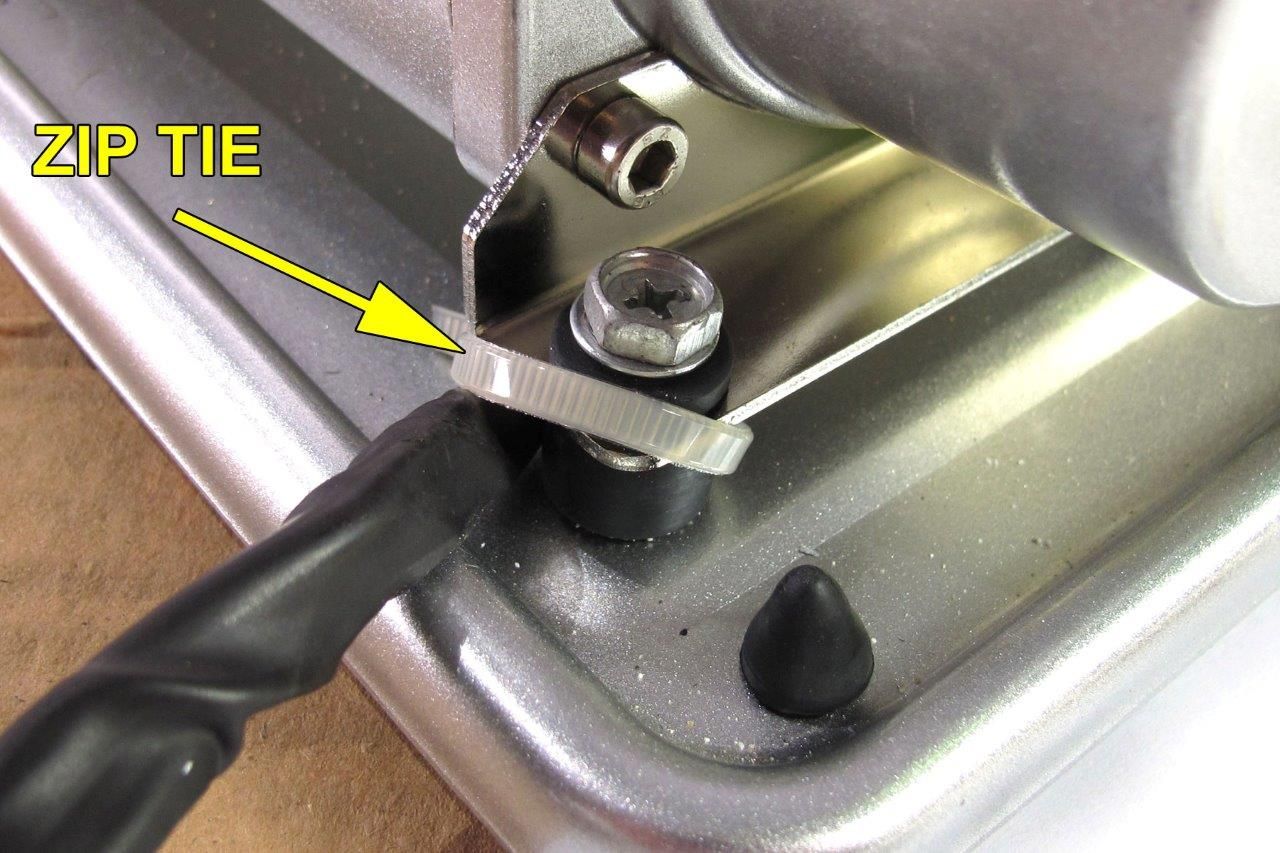

5) Make sure the zip tie on the power cable is in place; replace this zip tie if missing or broken.

6) Inspect the battery clips for corrosion, splits in insulation or possible cracks in solder.

7) Inspect all cables, switches and hoses for any splits, cracks or loose parts.

8) Do a final inspection and run test on the compressor and pack it away in its bag or box ready for use.

Note: Any item that looks worn or perished should be repaired or replaced.

Anderson Style Cable End Socket -

We are launching a new product NEXT WEEK, we are in the process of packaging our weatherproof 50A plugs. These new plugs are fitted with silicone rear seals and a snap cover to keep them clean. They are a complete plug with lugs and springs and assemble in the same way as a regular Anderson style plug.

Great for cable ends, extension leads, trailer connections and machinery.