How to fit a remote switch to MK3 to MK5 compressors.

Here is a handy DIY modification that you can make to your compressor, it saves you running back to the compressor to switch off the compressor when moving from one tyre to the next. Using a 7m cord and our inline switch you can turn off the compressor from the end of the hose.

Parts required: 7m TW20 twin core cable, 1x Inline switch, silicone sealant, cable tie.

Tools required: Small flat screwdriver, Philips head screwdriver, soldering iron and solder, sharp blade, drill.

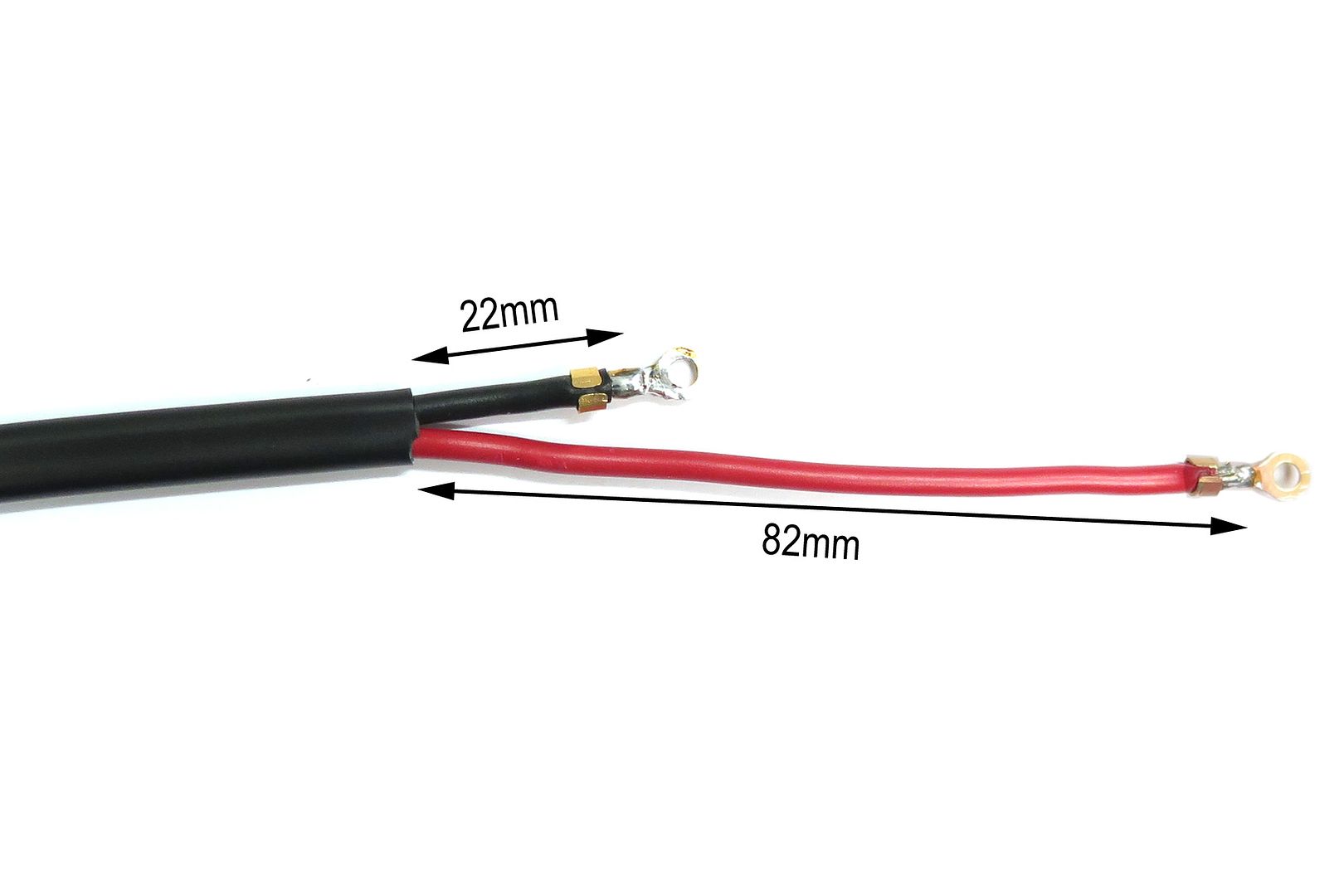

Start by trimming the cable as shown and soldering two

of the lugs from the switch to the wires.

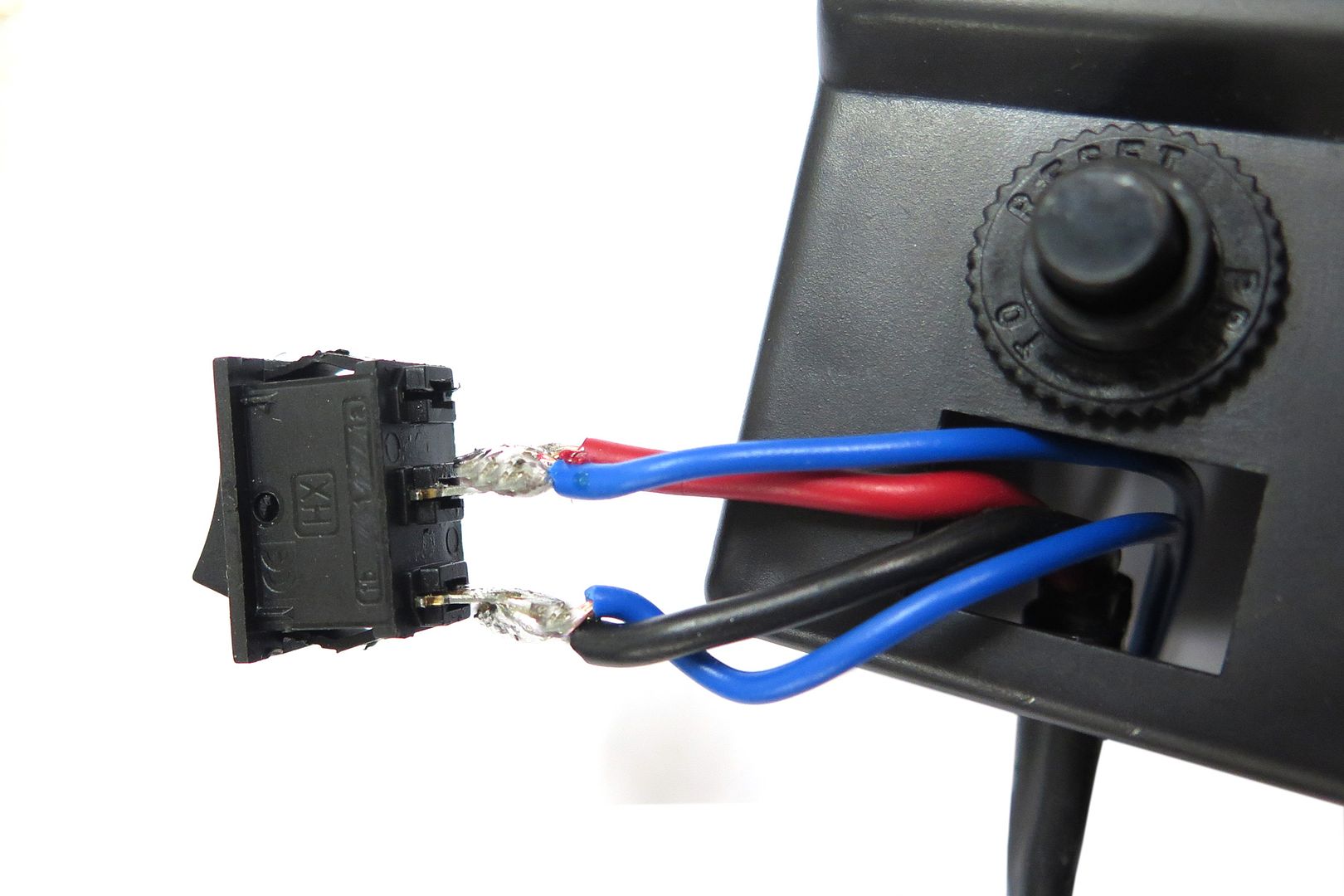

Connect the wires to the switch as shown using one pole of the switch. Make sure to thread the wire through the grommet.

Fit the rubber grommets to the switch case and close the switch.

Seal the open grommet to keep sand and moisture out of the switch.

Use a small flat screwdriver and pop the switch out of the compressor control box.

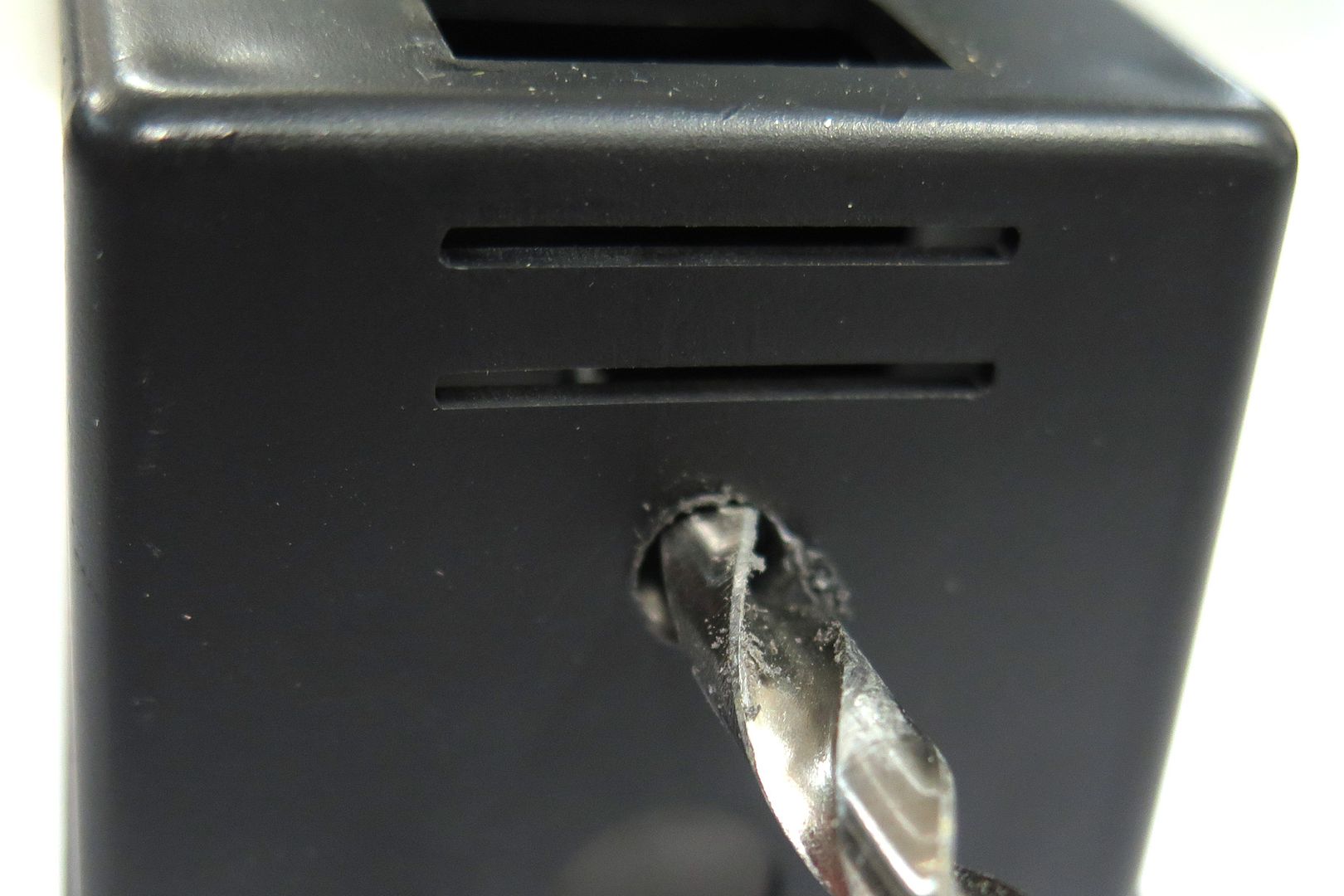

Drill a 6.5mm hole as shown. Take care not to drill into wires and the relay etc. inside the control box.

Prepare the cable, strip off 70mm of the outer insulation,

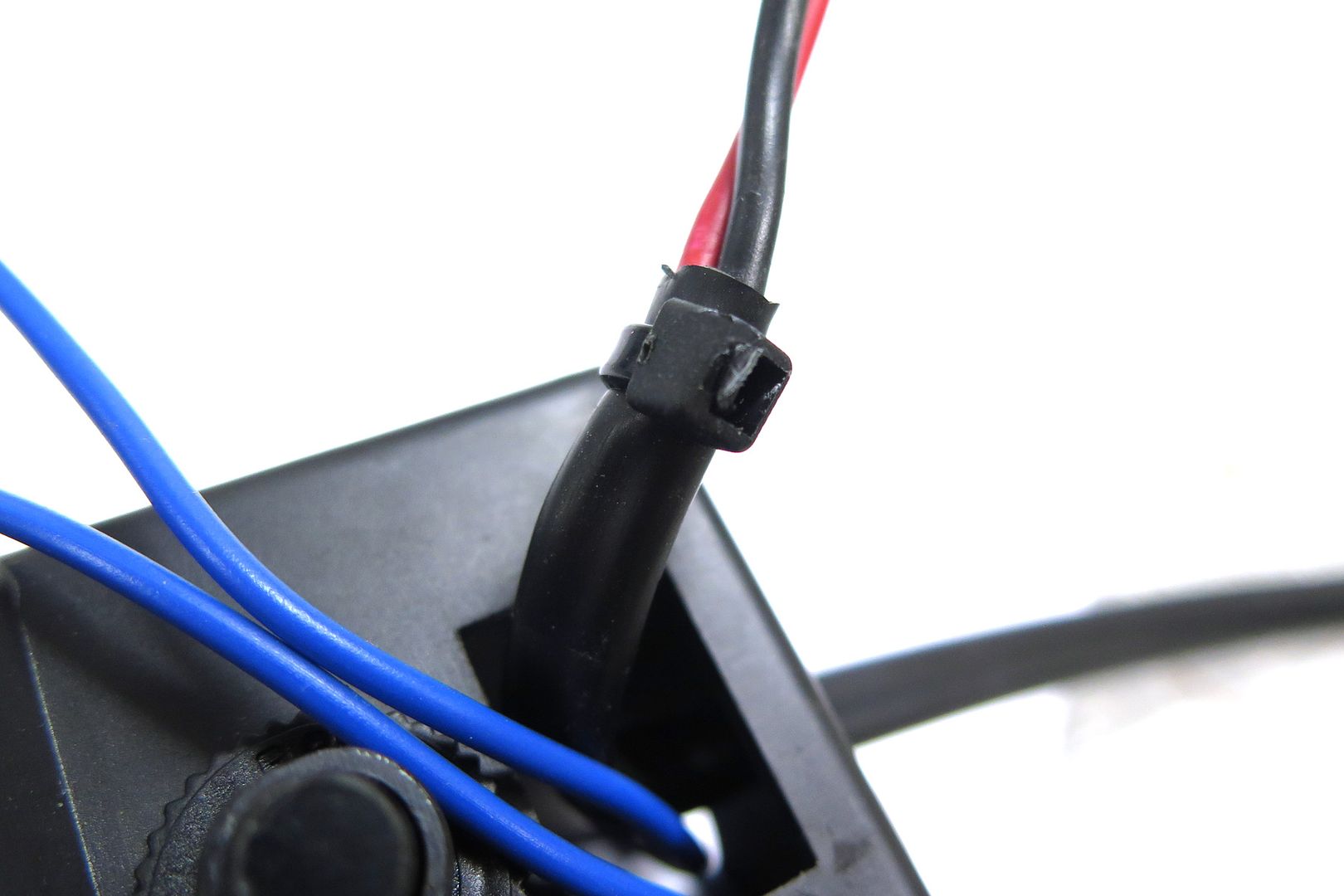

push the cable through the drilled hole and fit a zip tie to

the cable to prevent it pulling out the control box.

Pull the cable back up to the zip tie. Solder the ends of the cable as shown. Make sure not to over heat the switch. Tin the ends of the wires and quickly solder them to the switch.

Push the switch back into place and test the compressor. Make sure the compressor switch is in the off position when using the inline switch and vice versa.

Regards

Derek.